FAQ

Everything the Gearhead in You Needs to Know About the POWERPAK

If you don't see an answer to your specific question, or you'd like more information on a topic:

Watch Videos on Common Assembly Questions.

More Resources and Videos

Questions and Answers

Unfortunately, no. MAHLE manufactures a wide range of products, and each is supported by a unique group of customer service personnel. Our toll-free number, 888-255-1942, is dedicated exclusively to forged performance pistons and rings.

Other frequently requested numbers:

MAHLE Aftermarket (bearings, gaskets, cast replacement piston, etc.) 800-223-9152

MAHLE Service Solutions (shop equipment, AC & coolant service, etc.) 800-468-2321

Absolutely. We can build anything from a simple, one-off POWERPAK design to a full 3D billet piston with every feature imaginable added. Cost will obviously vary accordingly, and leadtimes are often impacted by current workload or time of year. Contact us for a more specific estimate on your order.

Discover the POWERPAK arrow_forward_iosAssuming both rings are the same thickness and you cannot measure the difference (1.0 mm vs. 1.5 mm vs. .043" etc.), the running face (or surface that contacts the cylinder wall) of the top ring will typically be a shiny silver or light grey color due to the face coating. The lack of face coating on the second ring will generally result in a ring that is black or dark grey on all surfaces.

Additionally, there are often physical features on the rings that can be used to tell them apart. For example, the tapered hook groove on the OD of a napier second ring or the presence of bevels on the ID of the ring. While the bevel alone does not definitively identify the ring, the combination of an upward bevel and a face coating will be the top ring. And likewise, a downward bevel and no face coating will be the second ring.

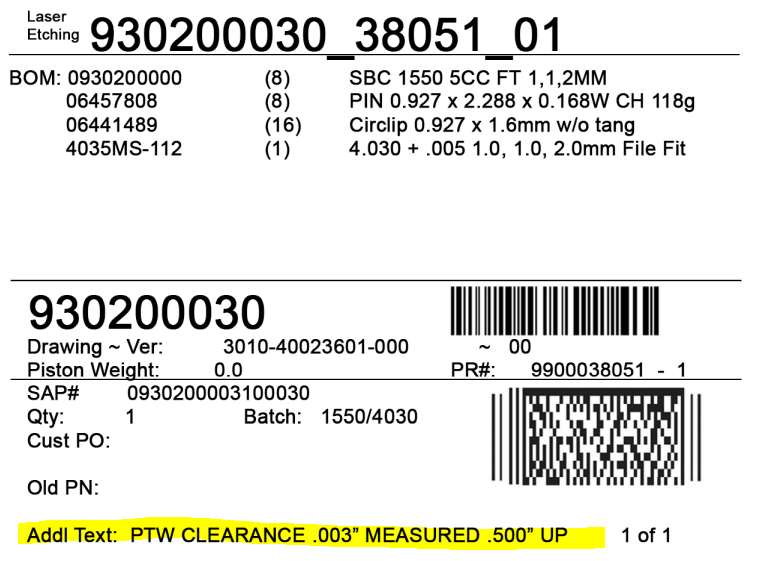

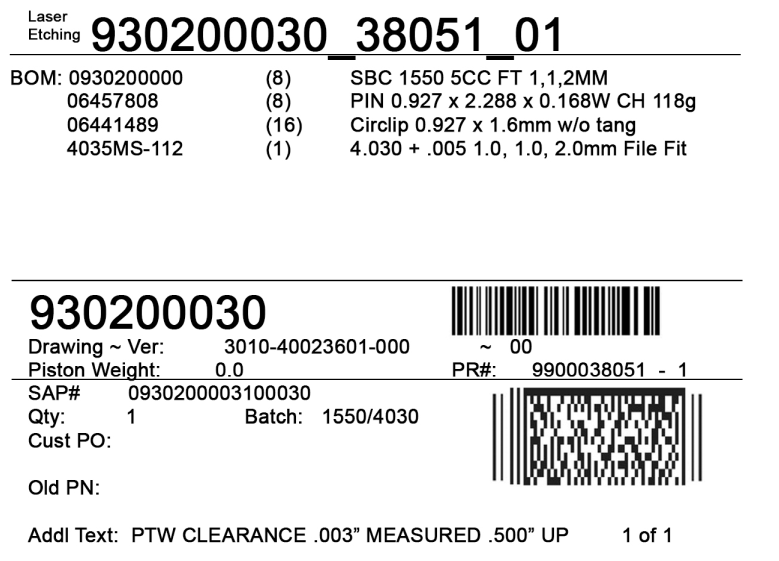

POWERPAK pistons have a unique part number and production batch information laser etched on the crown. For used pistons, this will require a gentle cleaning of the crown to reveal the number beneath any carbon build-up.

Some older, obsolete catalog numbers with an alpha-numberic format (i.e. SBC125030F05) may still be in circulation. Similarly, custom pistons use a variety of different markings that may be either on the crown or the underside of the piston. If you have a number that doesn’t align with anything in the current App Guide, let us know.

Additionally, you can often find another number embossed on the underside of the piston. This number typically follows the format ###P## (i.e. 101P44) and is a forging ID number. It cannot be tied to a unique piston part number because any one forging might be used for multiple different applications.

In general, all POWERPAK kits include forged pistons. However, a forged aluminum piston can be made from a variety of alloys, typically either 4032 or 2618. Exceptions include our diesel line of performance pistons, which include options for both cast and forged kits.

For more information on material choices, watch the video below.

All stocking and catalog parts are designed to accept popular cam combinations based on the intended application, but there are too many variables to create a definitive list. For example, duration and installed cam timing are often more critical to determining piston-to-valve (P-V) clearance than just lift. If you have a particular cam in mind, let us know, because P-V clearance should always be checked as part of the normal assembly procedure.

Clearance will be determined by the design of the piston, the piston alloy and the intended usage. Most pistons are designed with a target usage in mind, and we have those clearance values listed in our Application Guide, including the specific point on the piston where clearance should be checked. (We do not limit our designers by forcing every piston to use the same measurement point). The recommended clearance for POWERPAK pistons can also be found on the kit label.

Note that all clearance values are given as measured over the coating.

If you feel your application might fall outside the norm, please don’t hesitate to give us a call, and we will be happy to discuss.

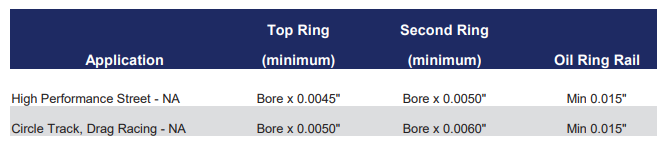

The amount of ring end gap required is more heavily influenced by the usage and/or application than by the specific material or type of pistons and rings (with the known exceptions for hypereutectic pistons). Our recommendation, based on usage, for ring end gap can be found in our ring guide. Most POWERPAK kits are supplied with file-to-fit rings, but the end gap should be checked on all applications as part of the normal assembly procedure.

Also note, the ring gap recommendations are supplied as a multiplication factor of bore size.

EX: NA Street, 4.030” bore: End gap = 4.030 x 0.0045 = 0.018”

File-to-fit gap recommendations are provided only for the top, second and oil ring rails. DO NOT modify the expander or wavy segment of the oil ring. The ends of the expander are designed to butt and must be compressed when installed in the bore. This provides the “spring force” required for proper function of the oil ring. A standard tension oil ring expander cannot be modified to create a low tension expander.

As a custom piston, any and all options are on the table. However, for a POWERPAK kit, we offer them off-the-shelf with a standard coating package included. Grafal and phosphate are the most common by far, but you’ll also find applications where we’ve added hard anodizing or other combinations that might be linked to rules and regulations for a particular class of racing.

Thermal barrier coating (TBC) for the crown is the sole exception. Whether custom or otherwise, we can add TBC coating to any piston you order. For POWERPAK, it’s as simple as adding ‘T’ to the kit part number.

930208225 - Standard kit with Grafal and phosphate

930208225T - Grafal and phosphate + TBC

Single pistons, components and single cylinder ring sets are available for all current production POWERPAK kits. Give us a call if you need help identifying any specific part numbers, if your kit contains Left and Right pistons, or for locating a distributor. Typically, however, the process is as simple as adding “-1” to the kit part number.

For example, kit PN: 930200030

1 single, replacement piston = 930200030-1

1 cylinder of replacement rings = 4035MS-112-1

Pins & clips are sold individually (no modified part number needed).

Example BOM:

1 Pin = 06457808

1 Circlip = 06441489

No. Quite simply because there isn’t one simple answer. The ultimate limit is dependent on the design of the specific part and your application or usage, which we’d be happy to discuss with you in greater detail one-on-one.

That depends. If you’re near the German state of Baden-Wurttemberg, you might commonly hear it pronounced (MAU-LUH). But here in eastern Tennessee and North Carolina, you’re more likely to hear us say (MOLLY). Truth be told, we don’t mind what you call us—as long as we’re who you call when you need pistons.